The design that we will build together derives from an open-source effort mainly driven by Peter van den Berg to adapt rocket stove technology for home heating. We envision hundreds or thousands of homes kept warm using our innovative design reducing heating costs and keeping carcinogenic wood smoke out of our clean air.

Plus the instructions are in video form which makes for a more thorough experience of actually being able to see someone put this stove together.

. Ad Every Month We Help Millions Find the Best Rocket Stove More. I saw this design. Easy to build requiring very simple brick and metal work and utilizing a clear simple layout.

In order to make a new arrangement just take the existing batch box riser port and all and turn it on its side. This is the minimum temperature needed to maintain a draught. The batch rocket combustion core is a cast item which is protruding out of the side of the barrel cylinder.

On top of that storing that heat in masonry allows the heater to stay warm eight or more hours after the burn. The Walker Batch RMH is a beautiful small heater perfect for a small cabin living room greenhouse. Arrange 2 concrete pavers into a T to form the base of your stove.

ROCKET STOVE DESIGN GUIDE The first step is to decide which kind of combustion chamber you want to put in your rocket stove. I placed mine on top of the firebox but it could go anywhere although a riser thats going down would be a bit much to ask without a fan. In fact a batch box rocket already has some features in common with a wood gasifier.

The BatchRocket heater is designed to have an flue exit temperature of between 120 to 150 degrees. The way turbulence is invoked is significally different from a normal wood stove. Leave about 25 mm 1 around the perimeter when cutting out the lids the added strength keeps the barrels circular.

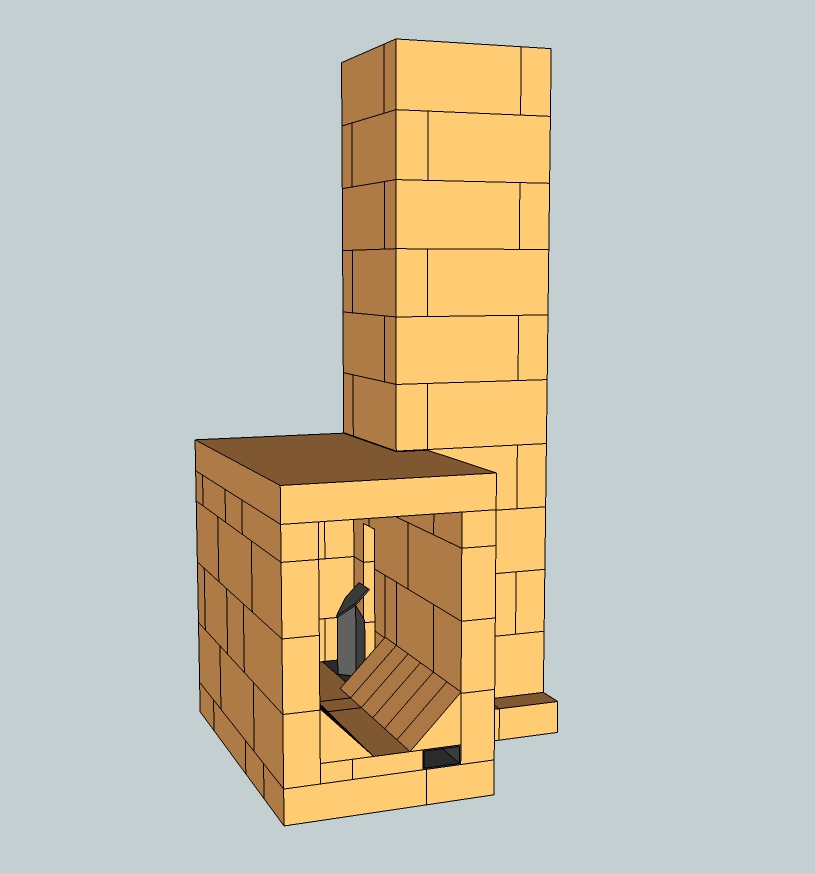

The combination of riser and combustion chamber is called the core. The sound is quite something when it make noise like that it runs completely without smokeThis video. See more ideas about rocket stoves rocket mass heater rocket stove mass heater.

In the Batch Box Rocket the tall and narrow opening at the bottom side of the riser is called the port. Plans are complete and include both brick layout and Super Hot Batch Core Plans no need to make a separate core plan purchase. English forums sometimes also referred to as PvdB BBR since my full name is Peter van den Berg.

I am considering building my first rocket stoveoven I have built a pizza oven in the past and am looking to use this primarily for cooking and baking. The Batch Box Rocket style masonry heater is scientifically tested to burn seasoned wood at a greatly increased effeciency over a traditional wood stove. The BatchRocket is an application of the Rocket Stove and is a type of mass heater or masonry stove.

Batch rocket mass heater plans and builders guide. First run of my final design batch box rocket heater. Our state-of-the-art stove design is leading a heating revolution in Portugal.

Brick rocket mass heater plans and builders guide. Superhot ceramic fiber rocket stove and heater core plans. For reasons you know too well a conversion from J-tube to batch box is natural during the process mine and others.

See the diagram below. Im sold to the idea and Im dedicating a lot of time and efforts to it but I digress. Join ABC acres a Permaculture Farmstead in Hamilton MT as we share FREE design plans for our rocket mass heaters batch box.

Walker PRe-port Secondary air. The type of combustion chamber will change the dimensions of the rocket body and the size of the shelf. During the workshop we constructed.

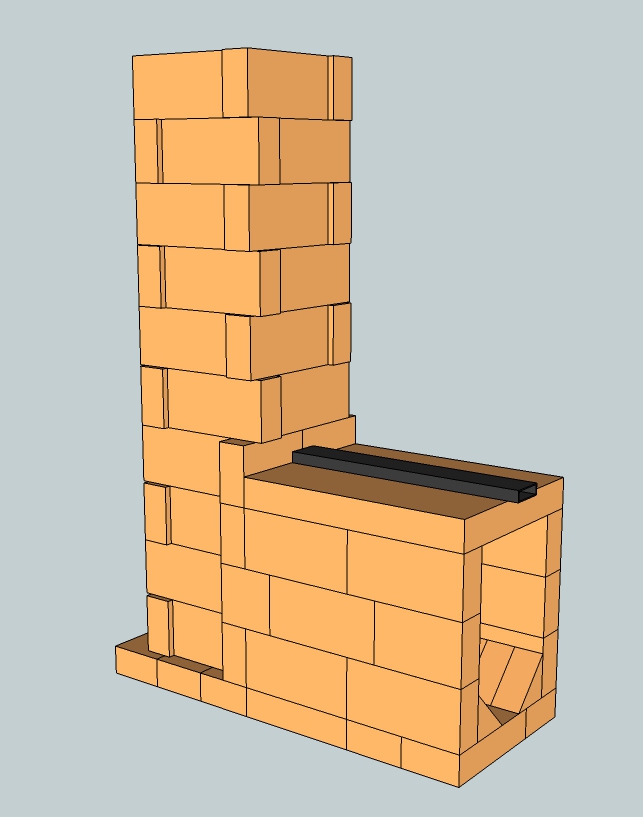

This website is meant to be a central information resource of what is called the Batch Box Rocket sometimes Rocket Batch Box or RBB. Lay 1 cinder block horizontally and stand another vertically on the. Google Sketchup renderings sho.

Be sure to follow the directions for the appropriate size of combustion chamber. It is achieved by having an ideal size of inside surface area where the inside heat is exchanged with the bricks. It is achieved by having an ideal size of inside surface area where the inside heat is exchanged with the bricks.

The door that allows you to load. I also saw that people had done an oven to capture secondary heat for baking. This rocket stove is another design that seems very feasible to build and also very functional.

It is a device to combust wood with high efficiency and minimal pollution the core of a. It requires a minimal amount of materials and is built from brick so it should hold up. The lower barrel is open at the top and the top one is open at the bottom.

This is the minimum temperature needed to maintain a draught. We are determined to make a real difference with this heater. As it happened with me I didnt understand how a rocket stove works I studied it for several months and then built it two until now.

Walker Full masonry Cook Stove. Mar 10 2019 - Explore Erik Weavers board RMH Batch Box Peterberg Design on Pinterest. The BatchRocket heater is designed to have an flue exit temperature of between 120 to 150 degrees.

Multi source oven which I liked because there were multiple heat sources so I assume that the chef could regulate the temperature.

3d Animation Of Building Up The Batch Rocket Stove Youtube

Batch Rocket Mass Heater Plans Walkerstoves Com

Rocket Mass Heater Rocket Stoves Rocket Heater

Abc Acres Rocket Mass Heater Start And Batch Box Plans Episode 057 Youtube

Batch Rocket Mass Heater Plans Rocket Mass Heater Forum At Permies

Abc Acres Rocket Mass Heater Free Batch Box Design Plans Episode 058 Youtube

Heat Your Home With 1 10 Of The Wood Used In Conventional Wood Burning Stove Impressions Of A Holobiont

0 comments

Post a Comment